Introduction

As modern power infrastructure becomes more demanding, the need for high-capacity, reliable voltage conversion grows rapidly. A 2500 kVA transformer is a heavy-duty electrical component commonly used in large industrial zones, data centers, hospitals, substations, and renewable energy projects. But how much does a transformer of this size cost? What are the factors that influence its price? This article provides a comprehensive breakdown of the 2500 kVA transformer price, covering types, features, applications, and purchasing advice.

What Is a 2500 kVA Transformer?

A 2500 kVA (2.5 MVA) transformer is a medium to large-capacity transformer designed to handle substantial electrical loads. It facilitates the voltage transformation between the transmission level (e.g., 33kV or 11kV) and usable distribution levels (e.g., 0.4kV or 400V). These transformers are commonly deployed in high-load applications where stability and efficiency are critical.

Types of 2500 kVA transformers and Their Pricing

| Transformer Type | Estimated Price Range (USD) | Typical Applications |

|---|---|---|

| Oil-Immersed Transformer | $20,000 – $35,000 | Substations, factories, power utilities |

| Dry-Type Transformer | $30,000 – $60,000 | Indoor plants, hospitals, data centers |

| Amorphous Core Transformer | $35,000 – $65,000 | Energy-efficient, green building projects |

| Pad-Mounted Transformer | $25,000 – $45,000 | Urban grid systems, commercial zones |

Prices are subject to change based on materials, configuration, standards, and delivery region.

Key Technical Specifications

| Parameter | Typical Values |

|---|---|

| Rated Power | 2500 kVA (2.5 MVA) |

| Primary Voltage | 11kV / 22kV / 33kV |

| Secondary Voltage | 400V / 415V / 690V |

| Frequency | 50Hz / 60Hz |

| Cooling Method | ONAN / ONAF (Oil), AN/AF (Dry) |

| Insulation Class | A / B / F / H |

| Vector Group | Dyn11 / Yyn0 |

| Standards | IEC 60076, ANSI C57, IS 1180, etc. |

Factors Influencing 2500 kVA Transformer Price

1. Cooling Type

- Oil-Immersed Transformers are more affordable and efficient for outdoor use.

- Dry-Type Transformers are safer for indoor environments but cost more.

2. Core Material

- CRGO (Cold Rolled Grain Oriented) steel is the standard core material.

- Amorphous metal cores reduce no-load losses but raise costs.

3. Voltage Rating

- Higher primary voltages (like 33kV) require better insulation and bushings, increasing cost.

4. Efficiency Level

- High-efficiency or Tier-1 models (based on local energy regulations) are more expensive but lower operational costs in the long run.

5. Standards and Testing

- Transformers built according to IEC, ANSI, or GOST standards may involve additional testing and certifications, influencing the price.

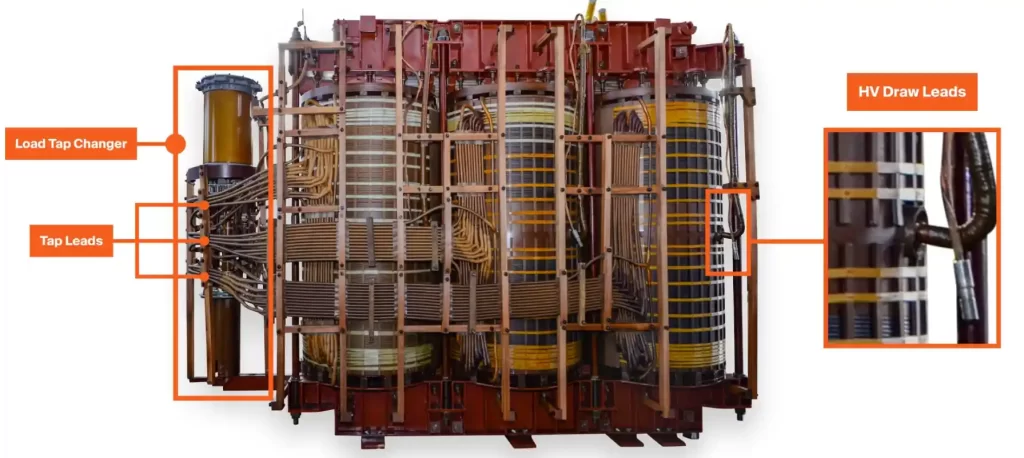

6. Accessories

- Tap changers (manual or automatic)

- Temperature and pressure gauges

- Protection relays

- Smart monitoring devices

Use Cases of 2500 kVA Transformers

- Large Industrial Complexes

Powering high-load equipment like motors, pumps, presses, etc. - Hospitals and Airports

Requiring stable, uninterrupted power supply for critical systems. - Data Centers

For high-density server loads and redundancy power systems. - Wind and Solar Farms

Converting renewable power into grid-compatible voltage. - Municipal and Utility Substations

Serving residential and mixed-use neighborhoods.

Advantages of a 2500 kVA Transformer

- High Efficiency: Lower losses mean reduced operational costs over time.

- Load Capacity: Can power dozens of commercial units or an entire factory line.

- Longevity: Expected life span exceeds 25 years with proper maintenance.

- Customizability: Voltage ratio, cooling system, and protection gear can be tailored.

Frequently Asked Questions (FAQ)

Q1: How much does it cost to transport a 2500 kVA transformer?

Due to the size and weight (often 3 to 6 tons), shipping can cost between $1,000 and $5,000 depending on distance and method (land or sea).

Q2: What is the weight of a 2500 kVA transformer?

Oil-immersed units typically weigh 3,000 to 6,000 kg, depending on the design and materials used.

Q3: Can I customize the voltage ratio for a 2500 kVA transformer?

Yes, most manufacturers allow for custom voltage configurations, vector groups, tap settings, and enclosure types.

Buying Tips for a 2500 kVA Transformer

- Compare Quotes from Multiple Suppliers

Prices can vary significantly based on region, materials, and logistics. - Request a Type Test Report and Compliance Certificate

Ensure the transformer is built and tested to international standards. - Check After-Sales Support and Warranty

A solid warranty (12–36 months) and local support team are essential. - Consider Lifetime Operating Cost

More efficient units may cost more initially but save thousands in energy loss. - Ask for Factory Acceptance Test (FAT)

For large-capacity transformers, testing before shipment helps reduce on-site risks.

Conclusion

The 2500 kVA transformer is a core asset for high-demand electrical systems. Its price can vary from $20,000 to $60,000+, depending on numerous technical and logistical factors. Whether your focus is industrial performance, energy efficiency, or long-term reliability, selecting the right transformer involves more than just comparing quotes—it’s about understanding your operational needs, compliance requirements, and total cost of ownership.

Careful planning, along with consultation from reputable manufacturers, ensures you receive a transformer solution that delivers safety, reliability, and cost-efficiency for decades to come.